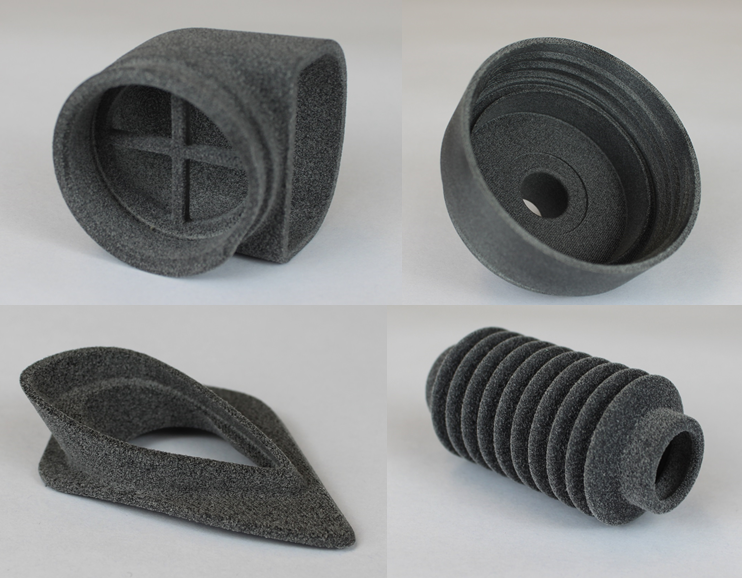

Components built in BASF Ultrasint ® TPU01, from Spring’s technical team, offer a good finishing, a high level of detail, a great shock absorption, a good UV resistance.

Moreover, with BASF Ultrasint ® TPU01 we produce parts characterized by an excellent resistance to oils, greases, hydrocarbons, oxygen, ozone.

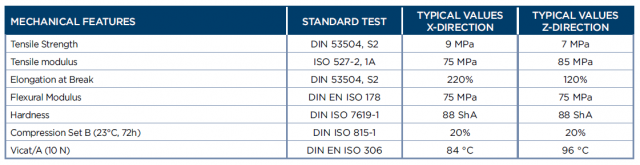

In the table below, it is possible to see some of the of BASF Ultrasint ® TPU01 mechanical properties.

In this link, it is possible to download BASF Ultrasint ® TPU01 data sheet.

BASF Ultrasint ® TPU01 for the production of components and prototypes in low volume

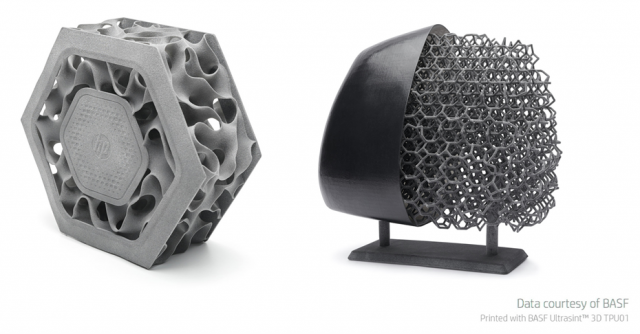

BASF Ultrasint ® TPU01 has been developed by Basf Group in partnership with HP, for HP Multi Jet Fusion printers.

Spring’s technical team is able to build components and prototypes in BASF Ultrasint ® TPU01, in short time and at low cost.

The technical staff is able to produce performing components in BASF Ultrasint ® TPU01, thanks to additive manufacturing expertises gained over the years.

We choose this material for projects that need flexible components, producing internal parts for automotive, ducts for liquid and gas, robot grippers, sleeves, tooling, seals and much more.

BASF Ultrasint ® TPU01: an application example

In the picture above it is possible to see an automatic machine component in TPU01, this component is known as code wheel cover.

This component needs to be frequently assembled and disassembled on the machine. These operations risk to damage other machine components.

The technical team has chosen additive manufacturing and BASF Ultrasint ® TPU01 material to build this component.

Thanks to additive manufacturing skills, the use of additive manufacturing technology and BASF Ultrasint ® TPU01 material, the company has taken the following benefits:

- Component design optimization: the code wheel cover has been improved for this specific additive manufacturing process. This optimization allows to assemble and disassemble the code wheel cover, without damage to the other machine components.

- Assembling and disassembling facilitation: thanks to the use of BASF Ultrasint ® TPU01 material, the code wheel cover is more flexible, this improvement allow to facilitate assembling and disassembling operations on the machine, reducing time for these operations.

- Reducing repair activities: An easier assembling and disassembling of the code wheel cover, without damage to other machine parts, allow to reduce repair activities on the machine.

- Reducing time and costs: Production time and costs have been reduced compared with standard production.

SPRING SRL – The additive manufacturing service for industrial applications

Spring srl offers 20 years’ experience in additive manufacturing, with a full service throught all process steps, guaranteeing a shipping time in few days.

The Spring’s technical team skills have allowed us to gain the certification ISO 9001:2015 in the production and supply of prototypes and industrial parts, and to gain the certification AS 9100:2016 in the additive production for the Aeronautic and Defense sector.

One of the most appreciated service is our «Design for manufacturing» that allow to optimize concepts for additive manufacturing process, guaranteeing the best value for money.

We guarantee our customers to treat confidentially all of information, data and documents of projects submitted to our attention. For more details on the Spring’s Confidentiality Agreement, click on the following link.

To have high quality components in few days and at low cost in BASF Ultrasint ® TPU01 material, contact our team on the following link.