Aviation and 3D printing redesigning the future of interiors

Over the next couple of years, passenger traffic will grow exponentially, forcing airlines to order thousands of new aircraft.

Major investments will be made primarily in innovating interiors. The solutions will not only offer passengers a positive flight experience but will also meet construction standards in terms of sturdiness, cost-effectiveness and reduced weight.

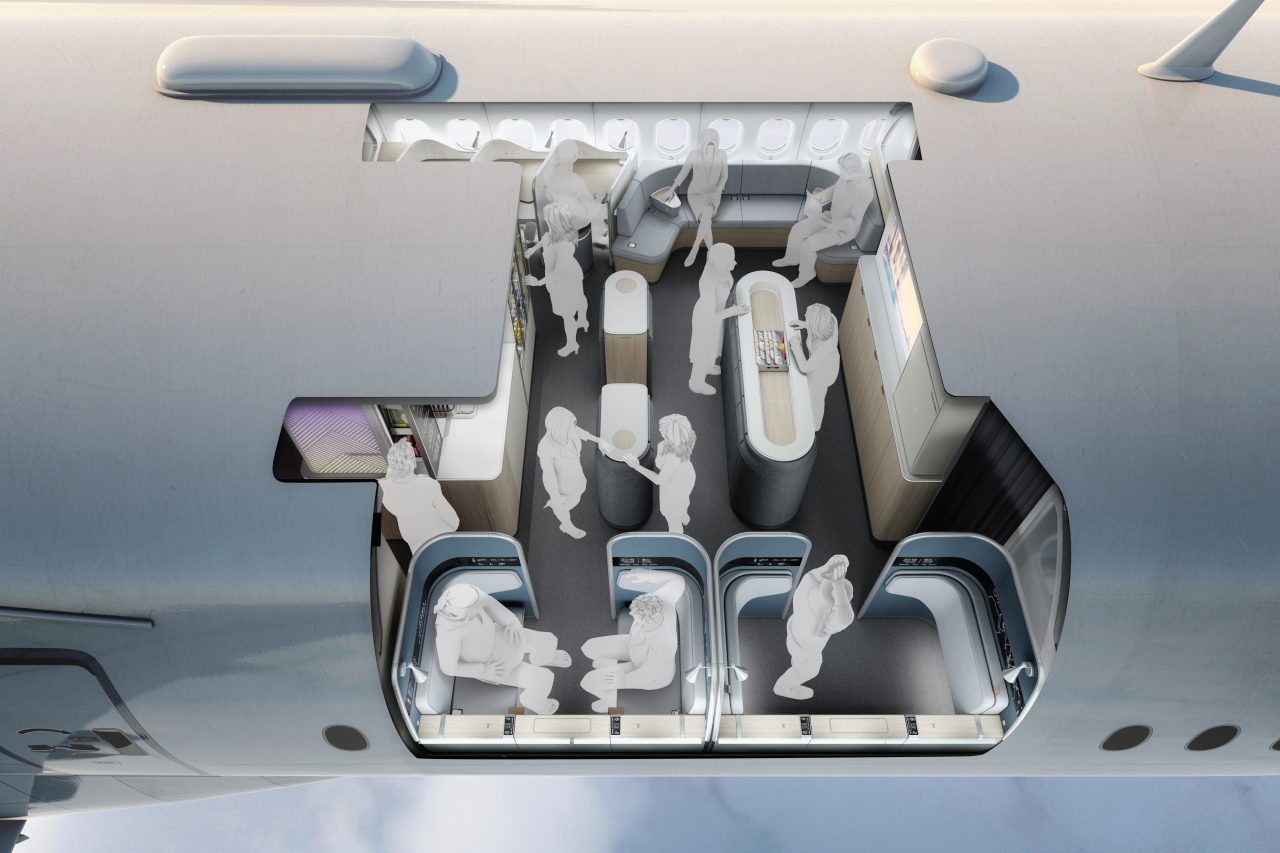

Interiors: the main areas of development

Redesigning interiors will lead to the creation of new modules for cabins, seating, onboard kitchens and bathrooms. The innovations will also include the air conditioning, electric, electronic cabin management, drinking water and waste systems.

Another interesting area of development is the in-flight entertainment and connectivity market. This sector includes software and design aimed at entertaining passengers as they travel.

The dawn of a new age

Unlike other sectors, such as the consumer electronics market, whose regulations are less stringent, the aerospace industry is rather conservative. However, we are at the dawn of a new age which is witnessing widespread implementation of innovative technologies.

According to Airbus, amongst others, 3D printing will have a revolutionary effect on the sector. So, it is no surprise to learn that the company has introduced more than 2,700 3D-printed plastic parts in its A350 XWB.

3D printing with FDM technology

FDM technology is a 3D printing process. Thermoplastic material is heated and goes from a solid to a semi-liquid state, enabling adjacent layers to be welded together. The FDM technology used by Spring S.r.l gives a significant reduction in time, weight and costs compared to producing the same parts using more conventional methods. Furthermore, 3D printing can produce highly complex geometries. This technology opens up a new world of possibilities, meaning engineers can completely rethink every single object. These important benefits have caught the attention of the aerospace industry.

Spring S.r.l: the number one partner for the aerospace industry

Companies can benefit from the wealth of knowledge, know-how and expertise Spring S.r.l has built up in over 20 years in the additive manufacturing business. The level of excellence achieved by Spring in manufacturing parts for the aerospace industry has led to the company being awarded AS9100:2016 certification, designed to meet the strict requirements of the sector.

Choosing the experience of Spring gives companies the edge over their competitors, allowing them to place innovative products with high added value on the market.

Images taken from: https://www.aircraftinteriorsinternational.com/features/the-top-24-aircraft-innovations-to-watch-in-2019.html