Case study: A motorbike Moto3 inlet pipe realization in carbon charged Nylon

Spring Srl designed and realized the inlet pipe of a Moto3 motorbike with Additive Manufacturing. The company set several targets to achieve the result:

TARGETS

- Reduce the costs of the detail

- Respect restricted delivery time

- Realize a detail with high technical characteristics

IMPLEMENTATION PROCESS

STEP 1: Design

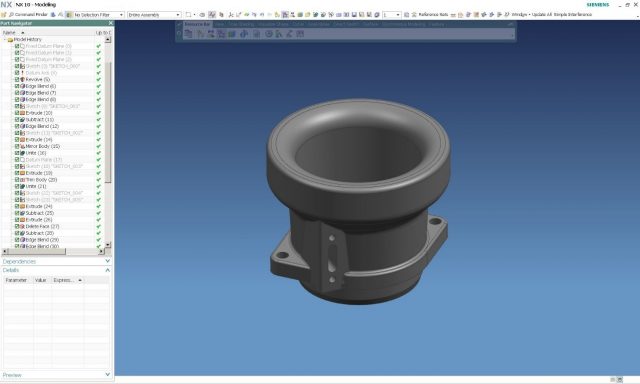

Once figured out the client’s requirement, the first activity was the inlet pipe design. The 3D model was developed with a CAD system installed in the company and successively optimized for Additive Manufacturing. During the design stage fixing points and casing for the temperature sensor were realized.

Cad design of the inlet pipe

STEP 2: Production

The applications in the Racing field require materials with high technical characteristics. The realized details needs to be resistant to extreme conditions as high temperature, chemical agents and significant mechanical stress. That’s why for the inlet pipe realization we chose Carbon Charged Nylon.

The material is composed by a mix of Nylon 15 with a 35% of carbon fiber. This combination makes it one of the hardest and with the highest resistance/weight ratio material available in the field of Additive Manufacturing.

Detail realized with additive manufacturing

STEP 3:Finishing

The detail has undergone an impregnation treatment to reduce roughness and improve performances. Afterwards, as customer’s request, inserts have been placed.

Post-finishing detail

STEP 4: Quality control

In the final phase the detail was tested with a quality control with a laser scanner. Spring Srl was able to guarantee the strict allowances requested.

Quality control detail

ACHIEVED RESULTS

Preavious solution | Spring solution | Difference | |

| Weight | – | – | -43% |

| Lead time | 2 working days | 1 working day | -50% |

| Costs | – | – | -31% |

Please send us your project to contatti@springitalia.com. It will be our prerogative to evaluate the technical feasibility and offer you the best possible solution!