Technologies and Materials - Spring

TECHNOLOGIES AND MATERIALS

Rapid prototyping (RP) technology quickly fabricates complex geometry models starting from measuring the physical part with a mathematical form on a 3D CAD model. Rapid Prototyping is normally used after designing and before manufacturing. Spring technology and materials allow instead to develop and produce an unlimited number of possibilities.

Rapid prototyping applications:

- Concept models

- Parts for fit and dimension testing

- Building of molds and fixtures

- Exhibition parts and materials

- End-use products

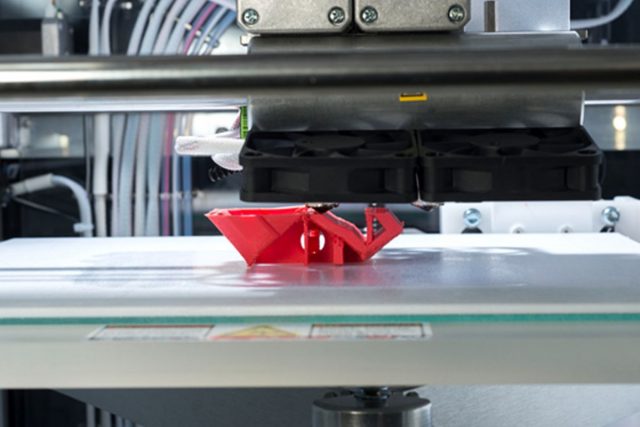

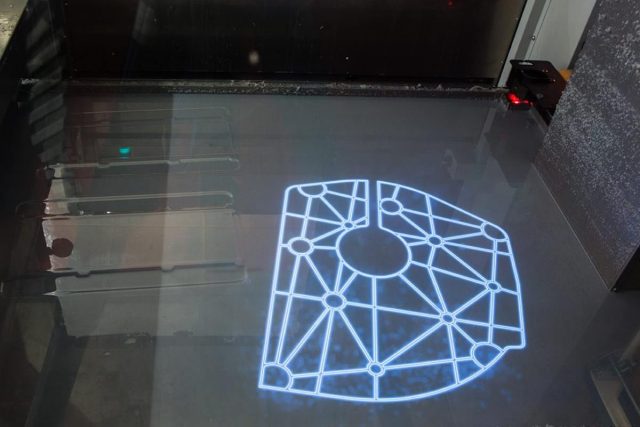

POLYJET

Polyjet rapid prototyping 3D printing technology is an advanced Stratasys-patented additive manufacturing method. 3D printers with PolyJet technology print 16-micron layers with accuracy as high as 0.1 mm for smooth surfaces, thin walls, complex shapes and end-use parts that fully match the characteristics of the end product.

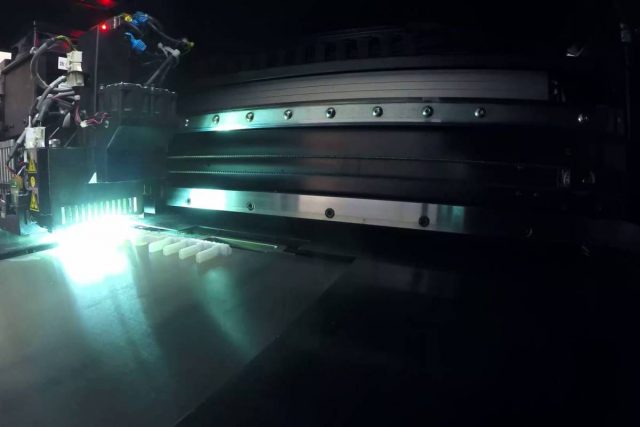

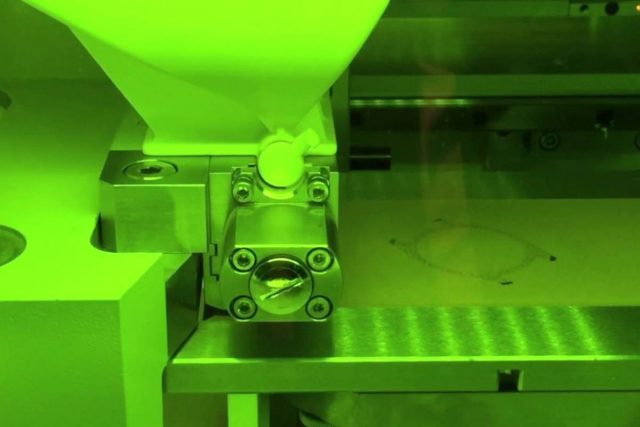

DMLS

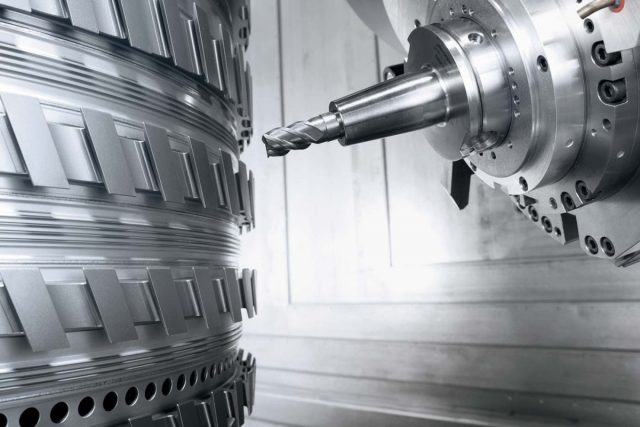

DMLS technology allows to manufacture prototypes and parts directly from metal without developing specific tooling. Parts and prototypes can be directly tested and used. The ability to develop high precision and accurate detail parts make DMLS technology useful also for the jewelry production industry. DMLS uses such materials as Titanium – Ti64 grade 5- that allow to produce medical and dental prosthesis.

ASSOCIATED WITH